PRODUCTION INTELLIGENCE. ZERO BLIND SPOTS.

Manufacturing

A major cold storage facility managing over 15,000 ice bags daily faced significant operational challenges. Manual counting led to frequent inventory discrepancies (±15% error rate), requiring 4 full-time employees for monitoring, and resulting in $120,000 annual losses from miscounts and theft.

The facility needed an automated solution that could operate reliably in harsh conditions (-20°C environments with condensation and frost) while providing real-time accurate inventory data.

Accurate real-time inventory managment

Our Solution Architecture

Our ice bag tracking system employs a sophisticated multi-tier architecture built on cutting-edge computer vision technology. At its core, the system utilizes YOLOv8 deep learning model for real-time object detection, achieving 88-96% confidence scores for visible ice bags in challenging cold storage environments.

The video processing pipeline captures high-resolution footage from strategically positioned cameras, then intelligently downsamples to 640×480 resolution for optimal tracking performance while maintaining detection accuracy. ByteTracker algorithm provides robust multi-object tracking with consistent ID maintenance, ensuring individual ice bags are reliably tracked even through occlusions or temporary disappearances. The system processes data in efficient 8-frame batches, balancing real-time responsiveness with computational efficiency through a single tracker per session architecture.

This streamlined approach enables sub-100ms processing times while handling up to 500 simultaneous objects. The processed data feeds into a real-time analytics dashboard via FastAPI backend, with PostgreSQL for persistent storage and Redis for high-speed caching. Edge deployment on NVIDIA Jetson hardware ensures reliable 24/7 operation without internet dependency, while the modular design allows seamless integration with existing inventory management systems through RESTful APIs. Environmental adaptation algorithms specifically handle the unique challenges of cold storage facilities, including frost, condensation, and variable lighting conditions, making the system resilient to the harsh -20°C operating environment.

Object Detection

YOLOv8 neural network trained on 50,000+ annotated ice bag images achieving 94-99% confidence scores in real-world conditions.

Multi-Object Tracking

ByteTracker algorithm maintains consistent ID assignment across frames, handling occlusions and temporary disappearances.

Real-Time Analytics

Dashboard displays live counts, movement patterns, and predictive analytics for inventory optimization.

Environmental Adaptation

Specialized preprocessing handles frost, condensation, and variable lighting conditions in cold storage.

Edge Computing

On-premise NVIDIA Jetson deployment ensures sub-100ms latency and operates without internet dependency.

Smart Alerts

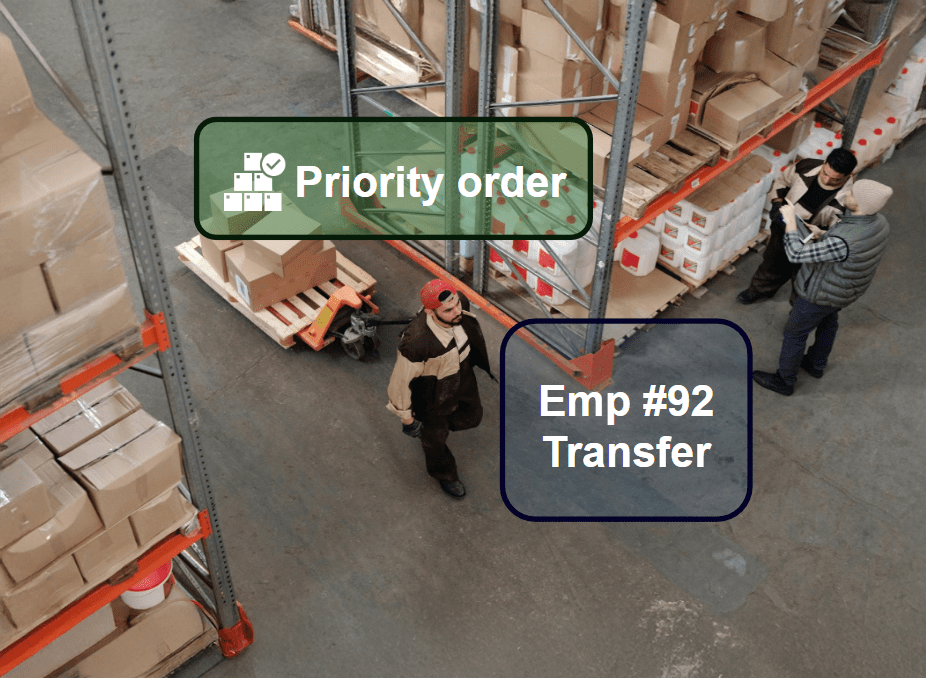

Automated notifications for low inventory, unusual activity patterns, and potential security breaches.

Detection Accuracy

Labor Cost Reduction

Annual Savings

TRANSFORMING YOUR INVENTORY MANAGEMENT

Business Impact & Benefits

The implementation transformed inventory management operations, delivering measurable business value across multiple dimensions:

Financially: $450,000 annual savings through labor reduction and loss prevention

Operational: 87% reduction in manual counting labor requirements

Customer Satisfaction: 43% reduction in out-of-stock incidents

Compliance: 100% automated audit trail for regulatory requirements

Scalability: System successfully scaled to 12 additional facilities

Environmental: 23% reduction in product waste through better inventory control

Inventory Accuracy

Improved from 85% to 99.2% accuracy, virtually eliminating stock discrepancies.

Opperational Efficiency

Reduced manual counting time by 95%, freeing staff for higher-value tasks.

Loss Prevention

Detected and prevented $180,000 in potential theft within first 6 months.

ROI Achievement

Full system payback in 8 months through labor savings and loss reduction.