WAREHOUSING

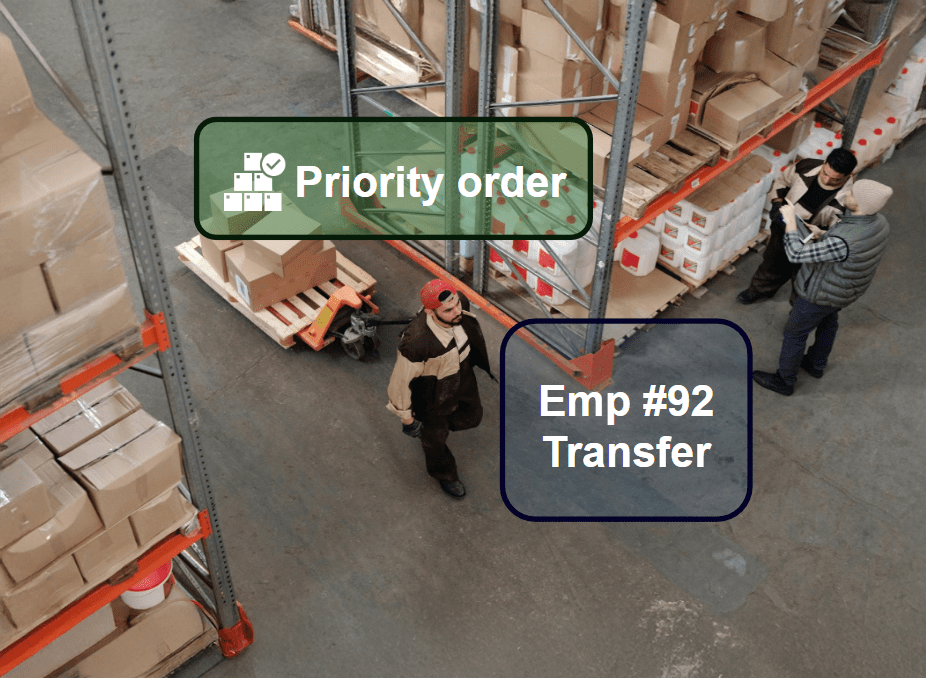

Warehousing is the backbone of supply chains, where efficiency, accuracy, and safety directly impact profitability. Computer vision brings automation and intelligence to warehouses by using AI to analyze visual data from cameras and sensors, helping operators streamline operations, reduce errors, and maximize throughput.

UbiVision can:

-

Automate Inventory Tracking: Continuously scan shelves, pallets, and bins to monitor stock levels, detect misplaced items, and update inventory in real time.

-

Increase Order Accuracy: Verify item selection during picking and packing, reducing fulfillment errors and ensuring customers receive the right products.

-

Optimize Space Utilization: Analyze warehouse layouts and traffic flow to maximize storage capacity and improve operational efficiency.

-

Monitor Equipment & Workflow: Track forklift and conveyor activity, identify bottlenecks, and provide insights to improve productivity and reduce downtime.

-

Enhance Worker Safety: Detect unsafe behaviors, monitor compliance with protective gear, and alert staff to potential hazards in high-traffic or restricted zones.

-

Reduce Loss & Damage: Spot product damage during handling, loading, or storage, helping operators minimize waste and maintain quality standards.

-

Enable Predictive Maintenance: Monitor visual cues on equipment for wear-and-tear to prevent breakdowns before they disrupt operations.

By adopting AI-powered computer vision, warehouses can achieve higher accuracy, reduce costs, and create safer, more efficient environments — building smarter logistics networks that scale with demand.